Domestic Speakers Webinar Series

December 2, 2021

Mattia Tiboni

University of Urbino Carlo Bo

3D PRINTING IN THE PHARMACEUTICAL FIELD: WHAT CAN WE ACHIEVE?

Abstract

Since 1986 when the first 3D printing technology has been patented, this manufacturing field has grown exponentially developing new techniques and inventing innovative applications. During the last decade, the interest in its usage for pharmaceutical related purposes raise dramatically. 3D printing has been explored to produce pharmaceutical forms, medical devices, manufacturing devices, and analytical devices. Here, we would show you the results of our research with the application of 3D printing. We were able to efficiently produce a 3D printed intravaginal ring loaded with clotrimazole. This ring showed a sustained release and an efficient activity against C. Albicans, the most common fungi in vaginal infections. Moreover, we developed 3D printed microfluidic devices firstly using polylactic acid (PLA) and then polypropylene (PP). Using them, we manufactured lipid and polymer-based nanocarriers in a controllable and tunable way. These devices resulted resistant to the manufacturing process with a very lower overall cost compared to commercially available microfluidic systems. Finally, we developed a 3D printed vertical diffusion cell that can be efficiently used instead of glass ones. We strongly believe that in the close future 3D printing will be used for the formulation of personalized medicines in pharmacies and that this technology will help the diffusion of personalized and low-cost manufacturing and analytical devices in research laboratories.

About Mattia

Mattia Tiboni is a PhD candidate in pharmaceutical sciences at the University of Urbino Carlo Bo. His main research interests are focused on innovative systems such as 3D printing and microfluidics with a particular interest in nanomedicine and nanotechnology

Silvia Pisani, PhD

IRCCS Fondazione Policlinico San Matteo, Otorhinolaryngology Department – Via Golgi 19, 27100 Pavia (Italy)

3D-SCAFFOLD FOR TISSUE REGENERATION IN ORL

Abstract

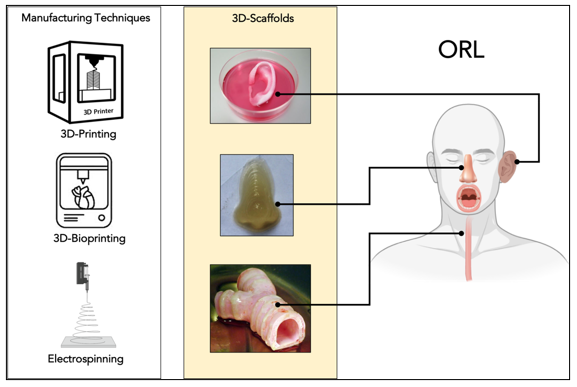

Otorhinolaryngology (ORL) encompasses the head and neck surgical management and reconstruction, for example after cancer surgical remotion. New frontiers in ORL surgery, involve the application of 3D scaffold to promote tissue regeneration and replacement after resection [1]. Rapid prototyping (3D-printing and 3D-Bioprinting) and Electrospinning, are manufacturing techniques widely used to produce polymeric 3D scaffolds able to mimic tissue’s physiology (Figure 1). 3D-printing and bioprinting, using a Computer-Aid- ed Design” (CAD) software, can produce objects starting from medical scan data. Instead, electropsun fibers, due to their nano-topography are able to mimic nature extracellular matrix (ECM). Lastly, for a suitable regenerative process, not only the scaffold geometry is important, but also the presence of cells and growth factors. Thanks to the versatility of these manufacturing techniques, is possible obtain 3D-engineered scaffolds selective for the specific function required [2]. In this webinar, the different 3D-scaffold manufacturing techniques are presented with advantages and limitations for ORL application. As a case study, a polymeric 3D scaffold for the regeneration of esophageal tissue is introduced. Manufacturing techniques integration, physico-chemical and biological characterizations, mechanical properties and in vivo surgical implantation in animal model are described [3].

[1] Canzi P, Magnetto M, Marconi S, Morbini P, Mauramati S, Aprile F, Avato I, Auricchio F, Benazzo M. New frontiers and emerging applications of 3D printing in ENT surgery: a systematic review of the literature. Acta Otorhinolaryngol Ital. 2018 Aug;38(4):286-303. doi: 10.14639/0392-100X-1984. PMID: 30197421; PMCID: PMC6146580.

[2] Nikolova MP, Chavali MS. Recent advances in biomaterials for 3D scaffolds: A review. Bioact Mater. 2019 Oct 25;4:271-292. doi: 10.1016/j.bioactmat.2019.10.005. PMID: 31709311; PMCID: PMC6829098.

[3] Pisani S, Croce S, Chiesa E, Dorati R, Lenta E, Genta I, Bruni G, Mauramati S, Benazzo A, Cobianchi L, Morbini P, Caliogna L, Benazzo M, Avanzini MA, Conti B. Tissue Engineered Esophageal Patch by Mesenchymal Stromal Cells: Optimization of Electrospun Patch Engineering. Int J Mol Sci. 2020 Mar 4;21(5):1764. doi: 10.3390/ijms21051764. PMID: 32143536; PMCID: PMC7084816.

About Silvia

Silvia Pisani, is currently postdoc at the Otorhinolaryngology Department of IRCCS Policlinico S.Matteo (Pavia). She got a degree in Pharmacy and PhD in Chemical and Pharmaceutical Sciences at the University of Pavia in 2019. Her researches involve electrospinning technique and rapid prototyping for manufacturing 3D-scaffold for tissue regeneration and drug delivery, their biologic and morphologic characterization. She was involved in NFFA- Europe (Horizon 2020 EU) project at FORTH (Foundation for Research and Technology-Hellas), Crete (Greece). She has been working in the research groups of Prof. Kit Parker DBG -Harvard School of Engineering and Applied Sciences, Boston, USA, Prof. Adriele Prina-Mello’s Lab at School of Medicine, Trinity College, and Prof. Bice Conti, Lab. Pharmaceutical Technology and Law (PT&L) , University of Pavia.

Giuseppe Francesco Racaniello

University of Bari

DIRECT CYCLODEXTRIN BASED POWDER EXTRUSION 3D PRINTING: AN INNOVATION FOR ONE-STEP PRODUCTION OF BCS CLASS II DRUG TABLETS